Commodity Number :

393-221-522-040

Commodity Name :

NcEditor 2022 Pro Ver. Siemens Milling Package

Commodity Introduction :

Intelligence CNC Program Editor for File Management, NC Coding, Cutting Simulation, and File Transmission. Excellent tool for learning NC coding and factory management.

Use Version :

Subscription Plan:

Commodity Price :

Product Specification

1 File Management

1.1 File Manager:

(1) File list: Enable the file comments browsing and picture preview

(2) File control: New file, new folder, copy, cut, paste

(a) New file: Build and edit new CNC program

(b) New folder: Add and set the folder comment, set the default machine type in the folder

(c) Copy, cut, paste: control file and attachments

(3) Recent files: Display latest edited files

(4) Search: Search file with file name or comments

(5) Refresh: Refresh file list

(6) Recycle bin: Display removed files

(7) Print folder: Print current browsing folder directory

(8) Local Ver. List

Professional Version Additional Features

1.1 Tree View: Display browsing window on the left side of the screen provides quick access to browse the folder

1.2 User management: user management and ID switching

1.3 Version file (purchased separately): manage different versions of the software through “CNC Archive Version Manage System”

2 Program Edit

2.1 Program edit:

(1) Program edition

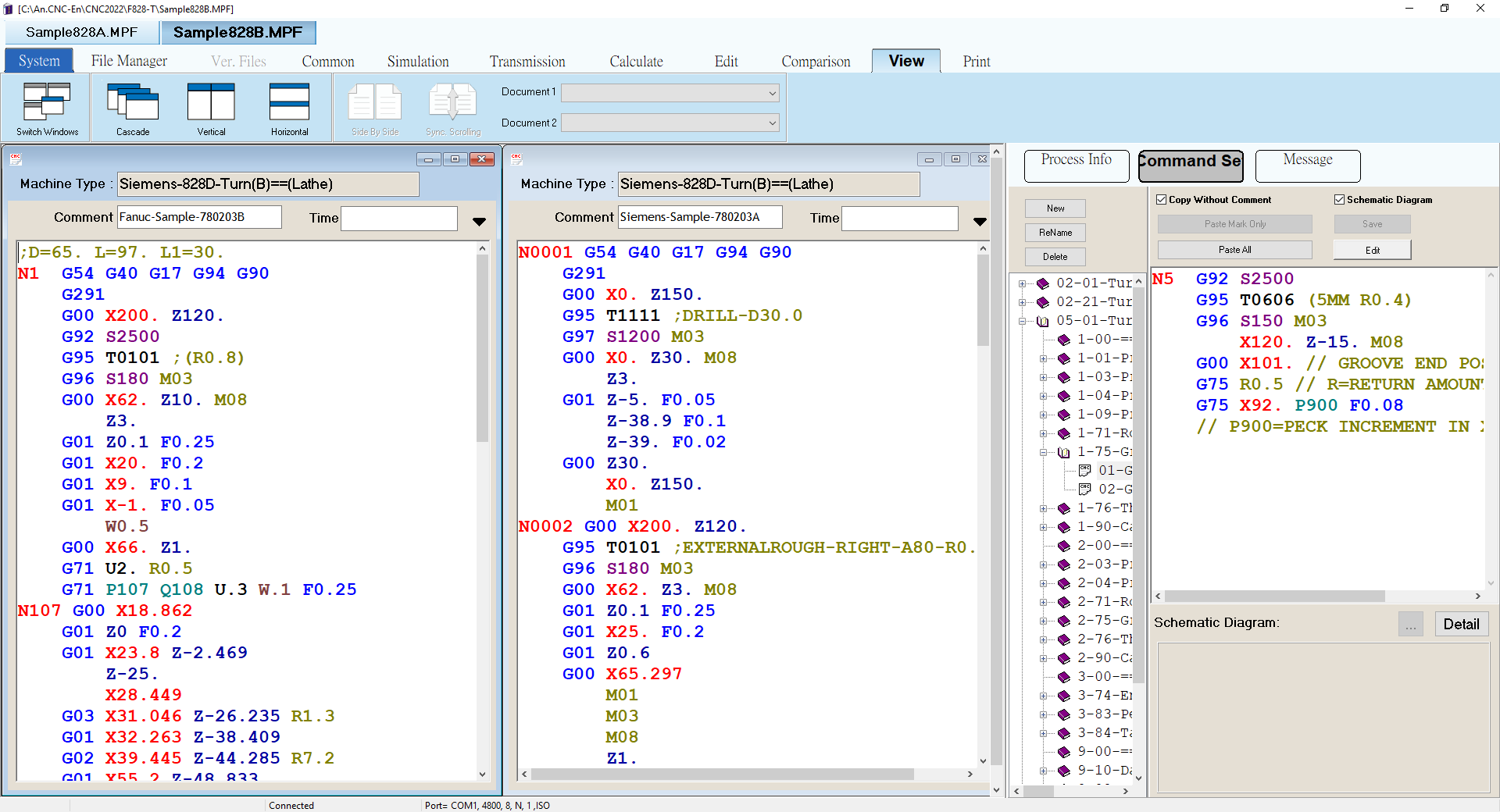

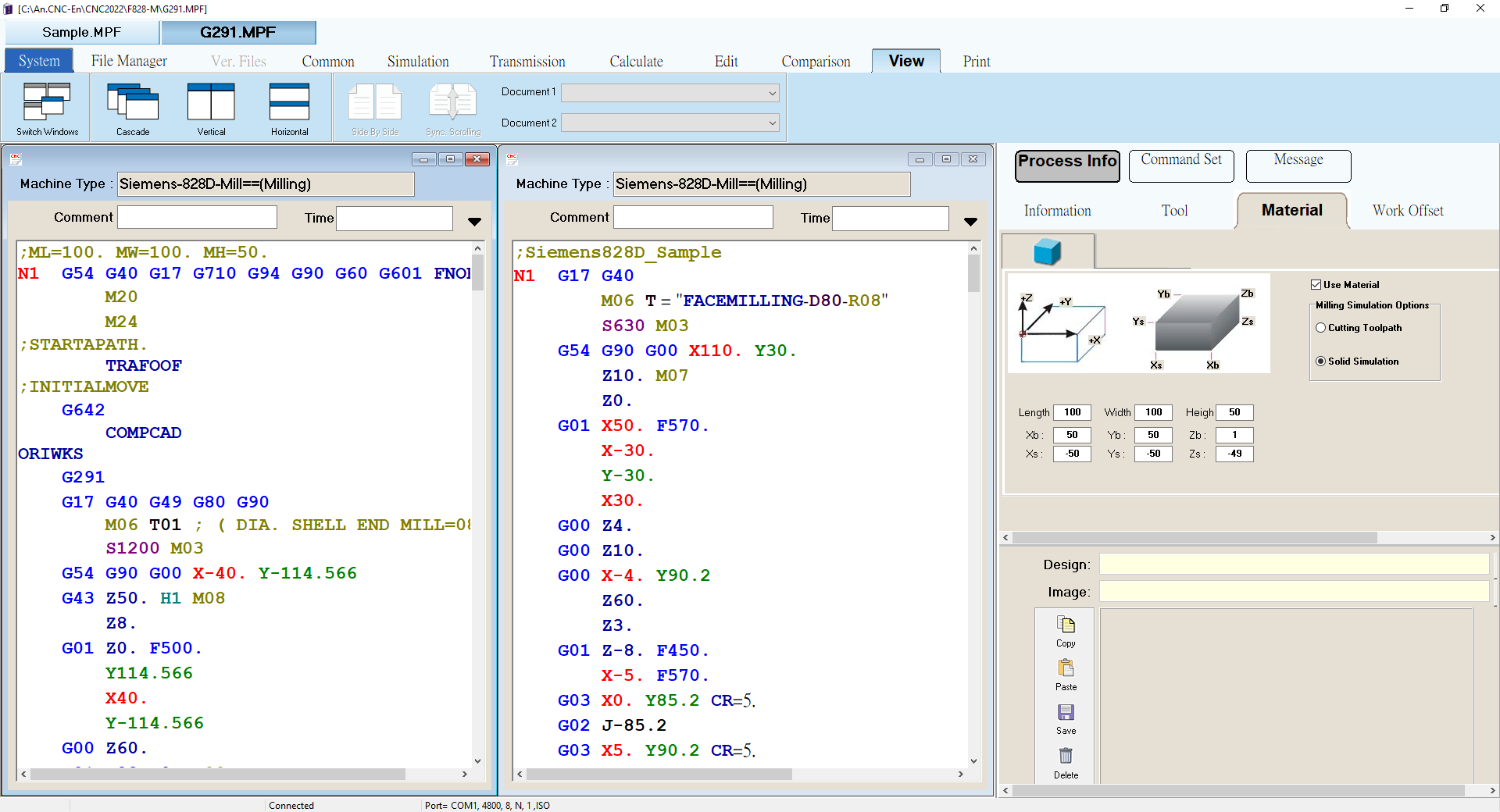

(2) Nc Codes with different colors and font are easier to identify.

(3) Comment text alignment is for the program code more readable

(4) Searching

(a) Search: quick search for target text

(b) Replace: search the target text and replace with new text

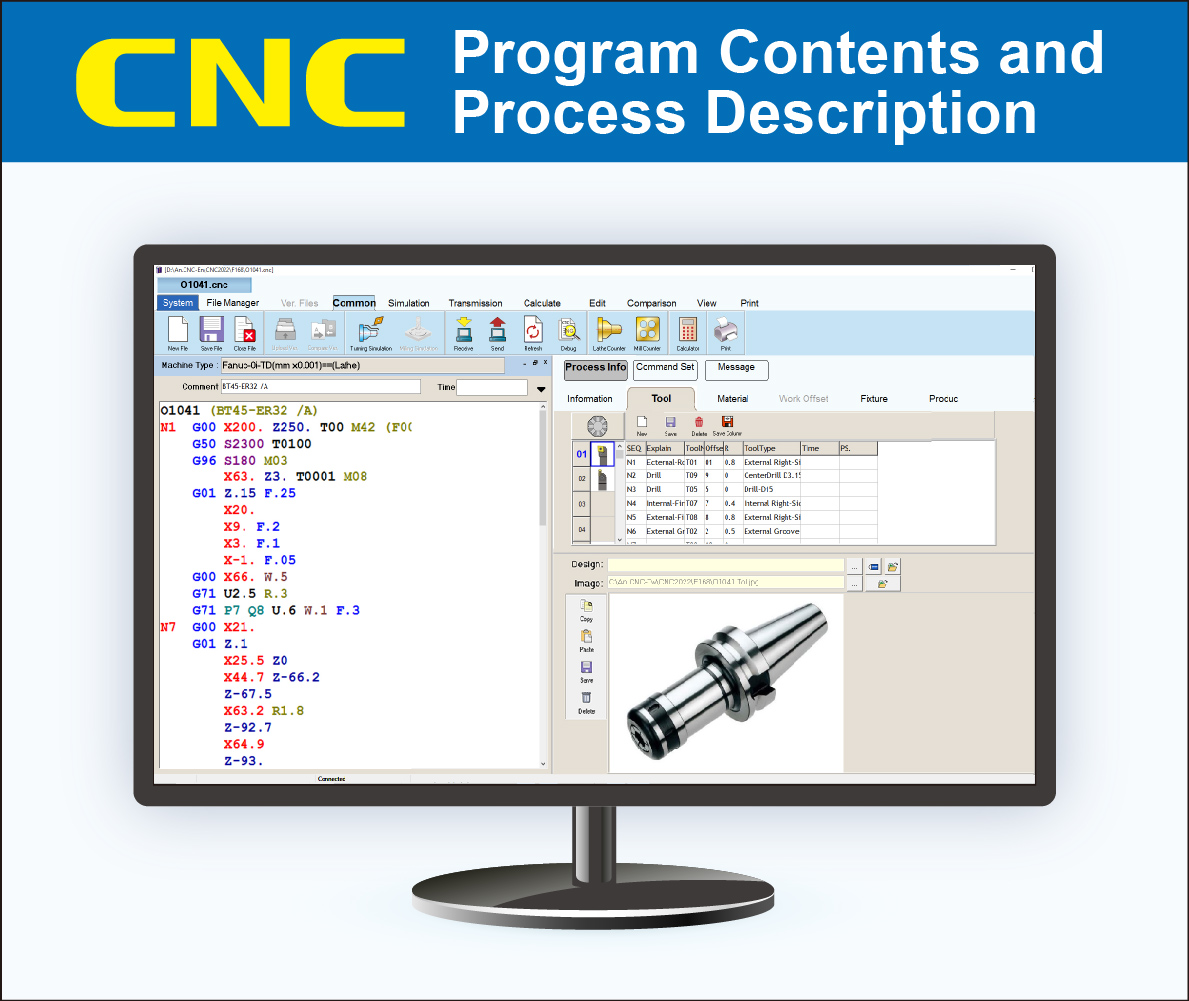

2.2 Process Info:

(1) Information: Edit the description and the image of the process

(2) Tool:

(a) Turret/Magazine: Select the tool to be installed, adjust the tool in the turret/magazine

(b) Edit the applied tool and comments of the tool comments.

2.3 Print: Print file, comments

2.4 Calculate:

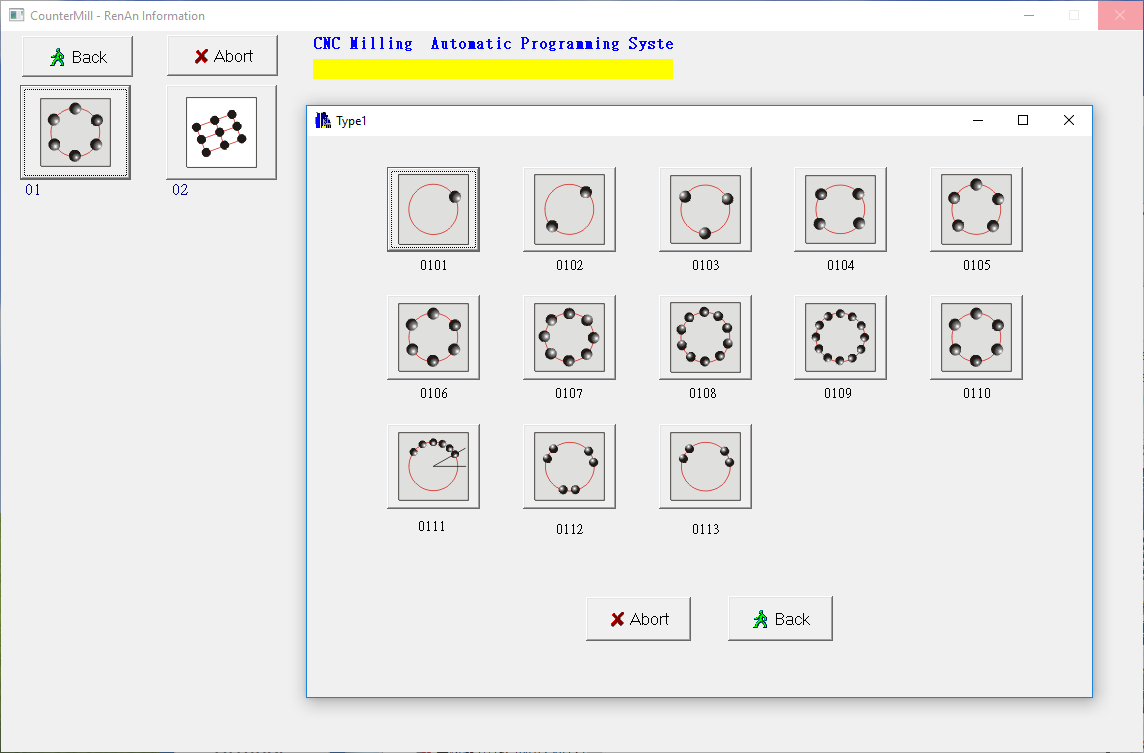

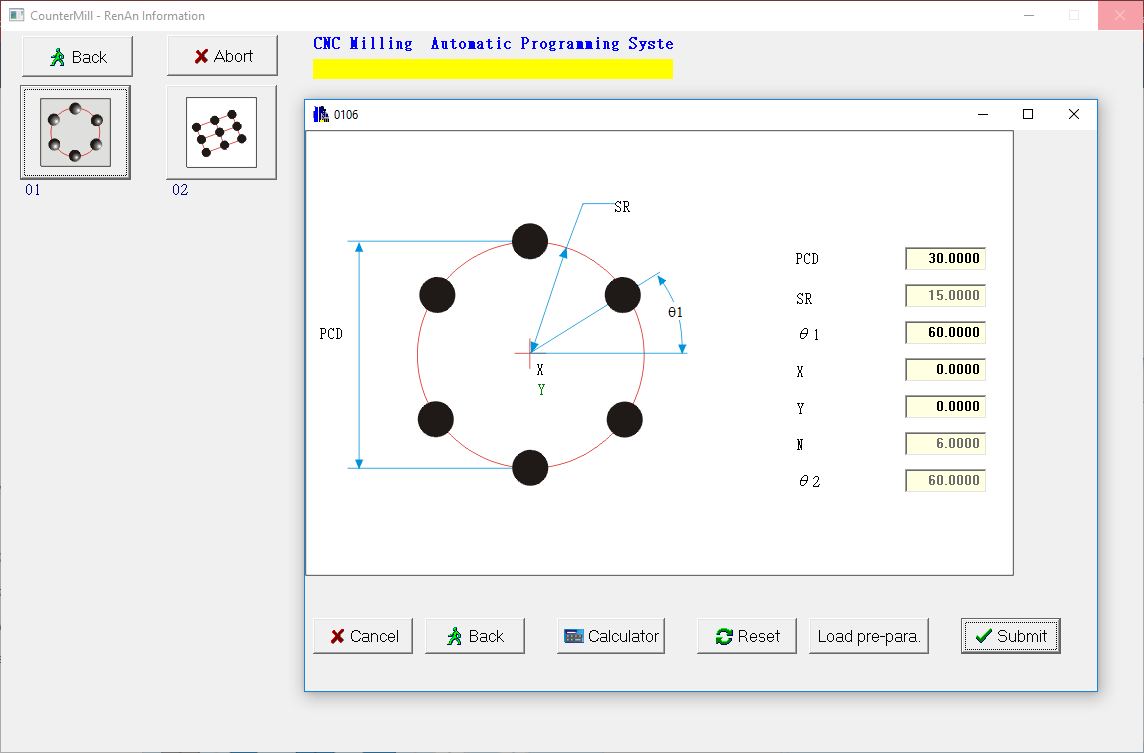

(1) Mill Counter: Peripheral hole tapping/drilling, Matrix hole tapping/drilling

(2) Calculator: The result can be imported to NcEditor after calculation

2.5 View:

(1) Side-by-side: display file 1 and 2 side by side

(2) Synch-Scrolling: simultaneously scroll file 1 and 2

(3) Switch Windows: switch to the current opening CNC program window

(4) Cascade windows, Vertically display, Horizontally display: CNC window display status switching

Professional Version Additional Features

2.1 Program edit:

(1) Search

(a) Go-to: skip to the specified sequence number N or tool code T or line

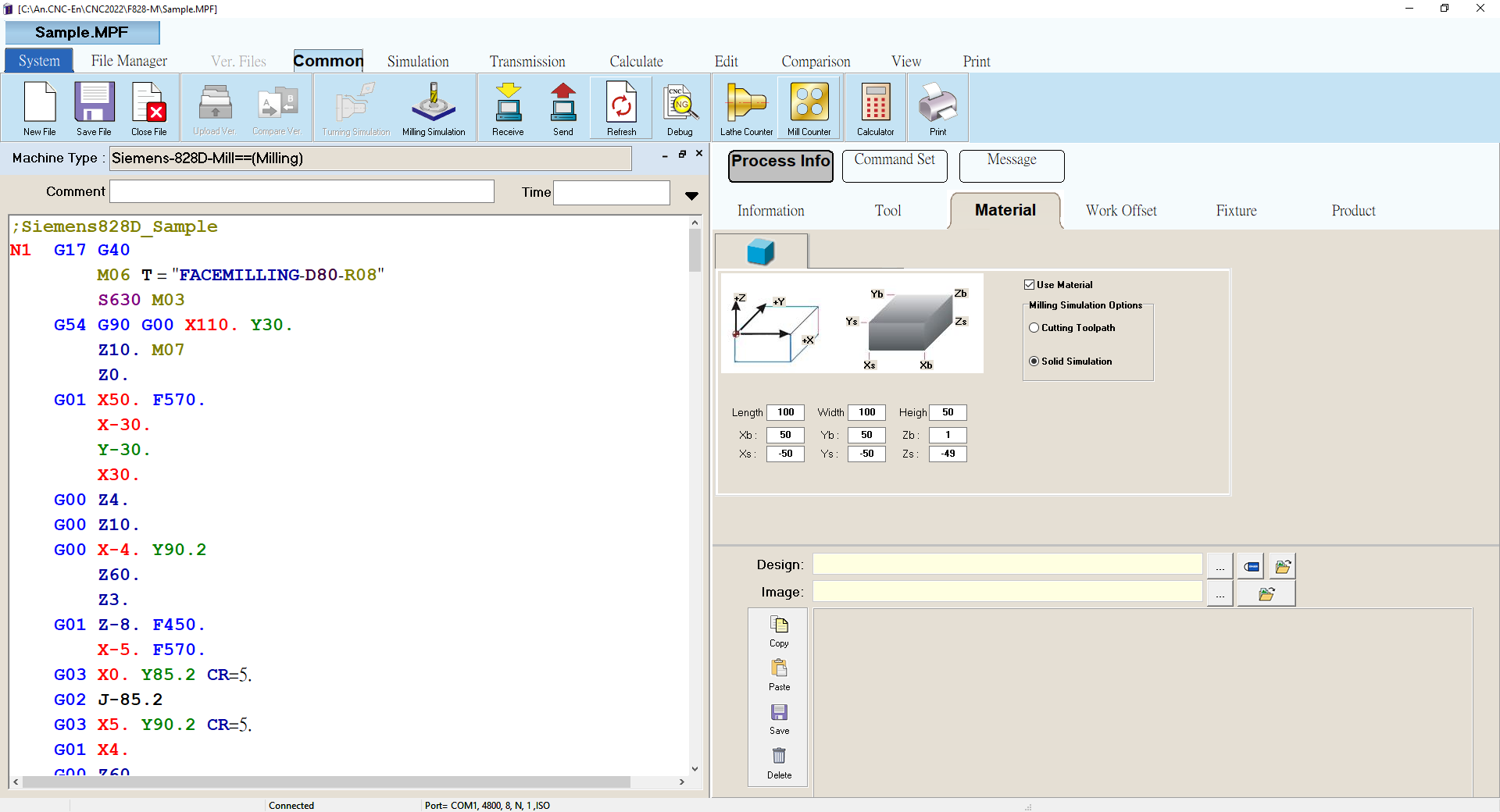

2.2 Process Info: work offset, material, Fixture, product

(1) Work Offset: set the work coordinate

(2) Material: set material dimension

(3) Fixture: Edit the description and image of the fixture

(4) Product: Edit the description and image of the product

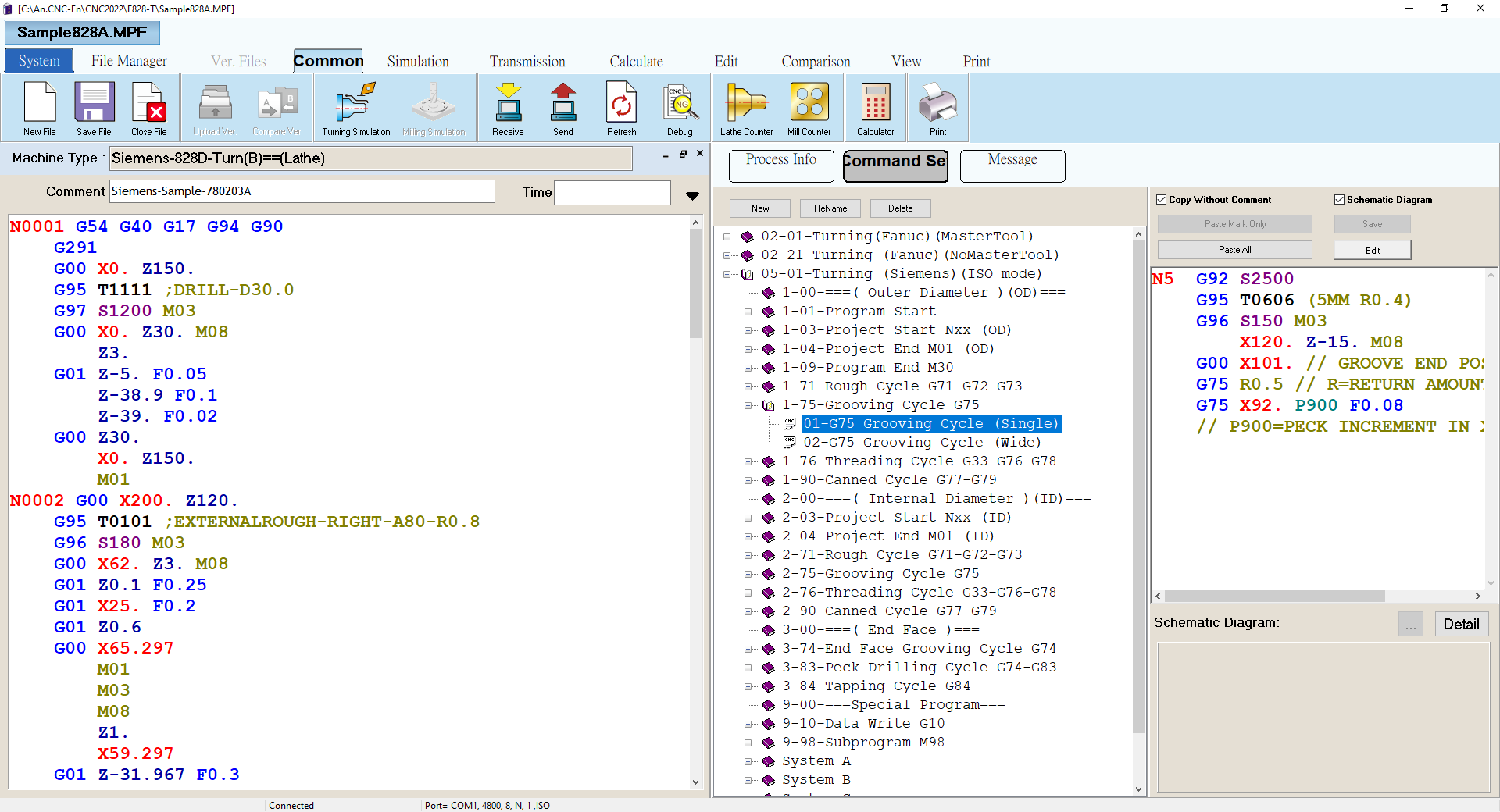

2.3 Command Set: The examples of the commands in the command set make program edition quicker and more convenient

(1) Commands list:

(a) Turning (Fanuc)( Master tool)

(b) Turning (Fanuc)(No master tool)

(c) Turning(Siemens)(ISO mode)

(d) MC machining center-Milling

(e) MC machining center- Tool Change

(2) Schematic Diagram: Display the cutting diagram that is relevant to the command

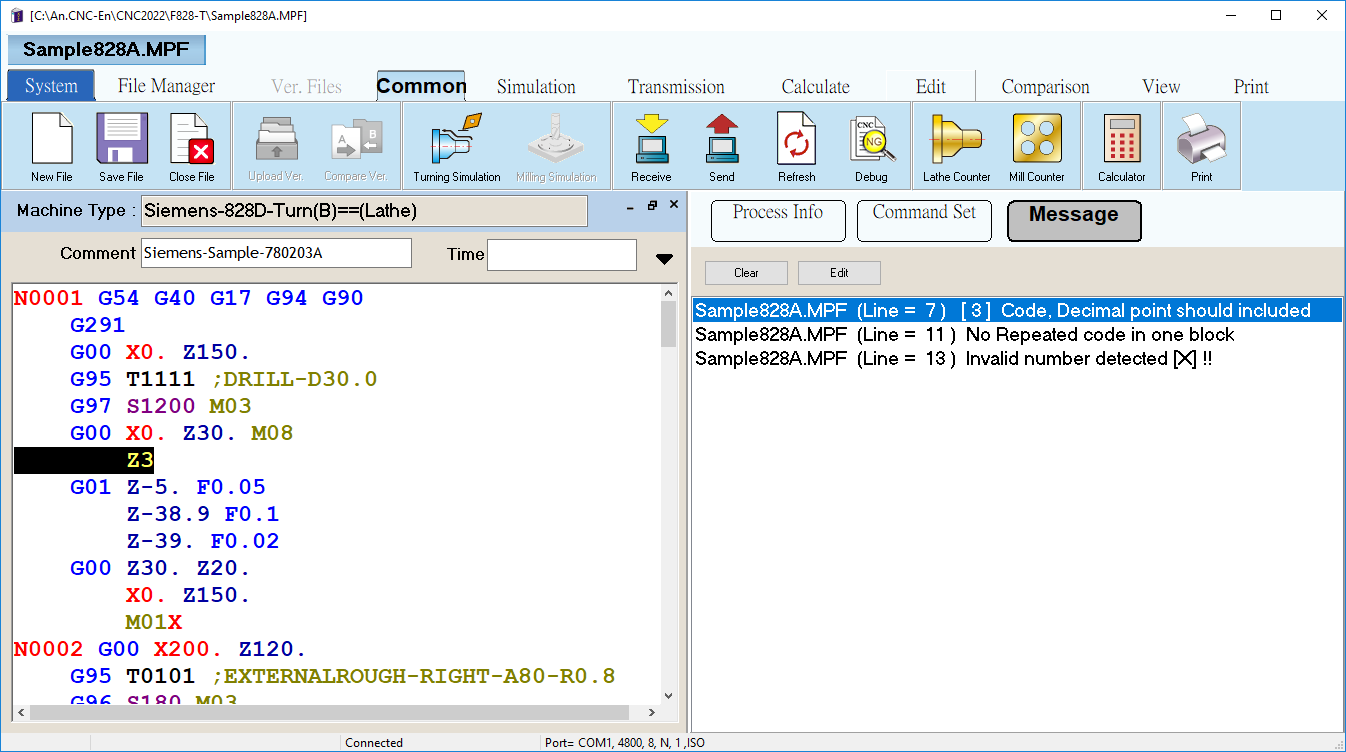

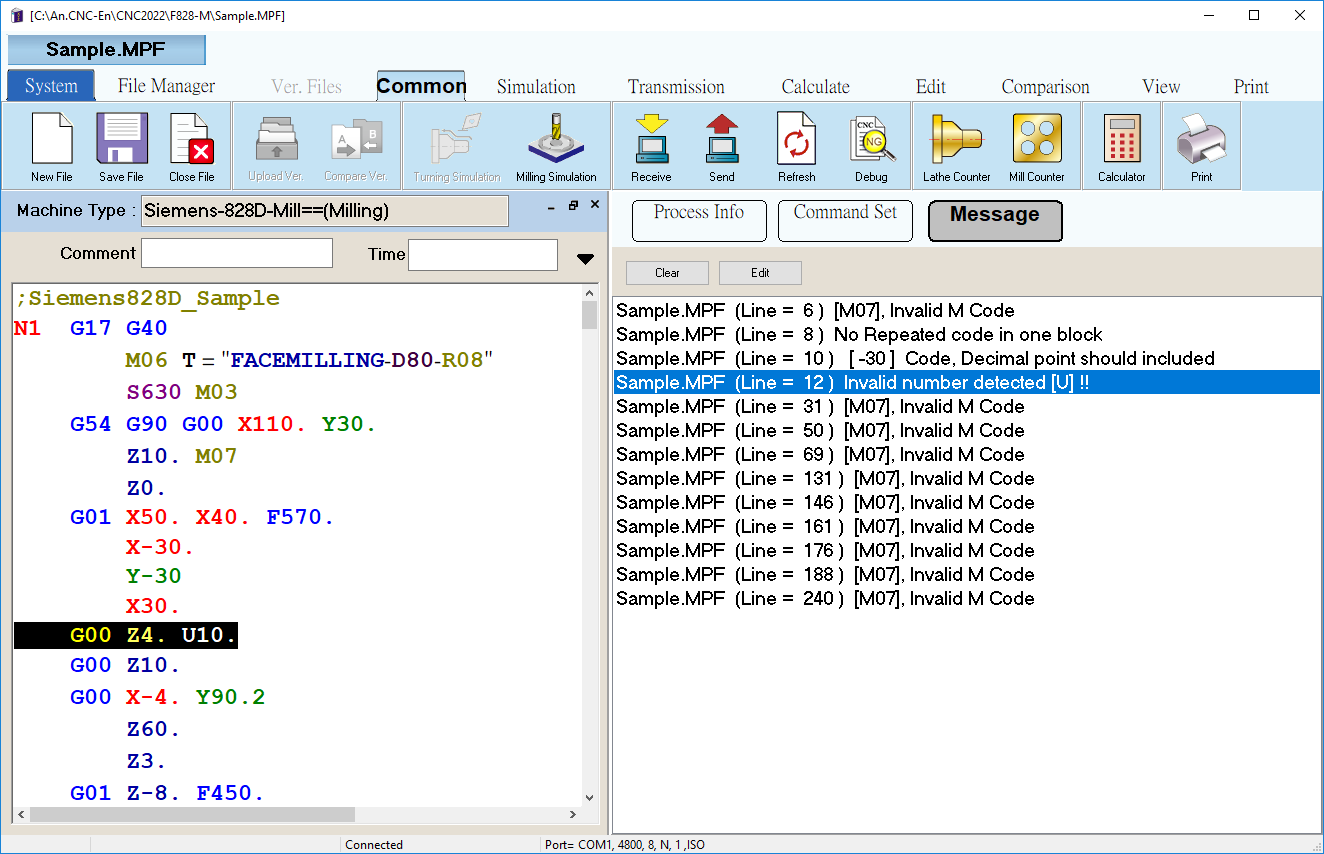

2.4 Debug: Set context debug mode or Syntax debug mode

(1) Context Debug: Debug the CNC program and display the error in the message

(2) Syntax debug: standard CNC mode, MACRO variable mode

(3) Message: After context debug, error message and block No. will be displayed.

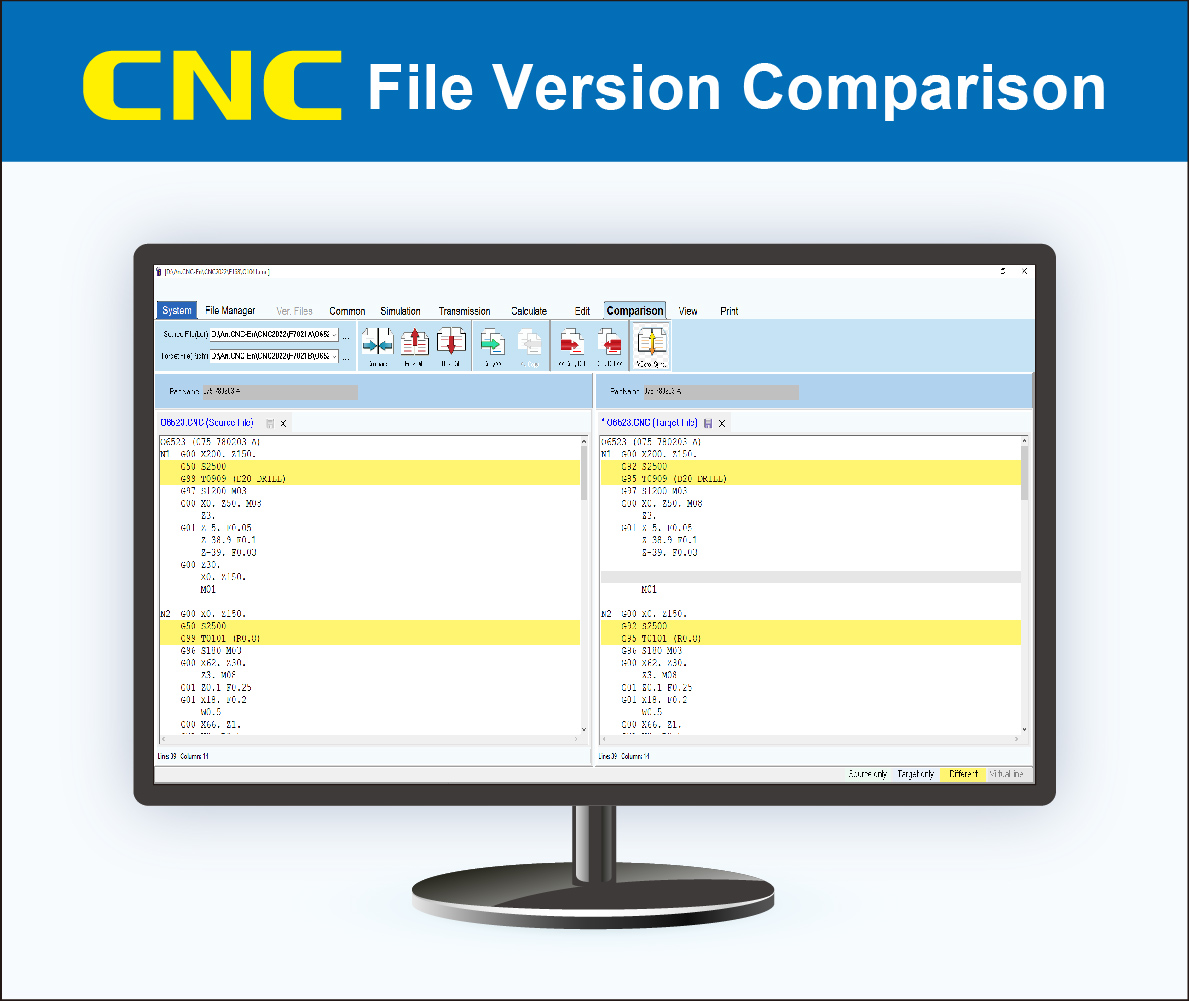

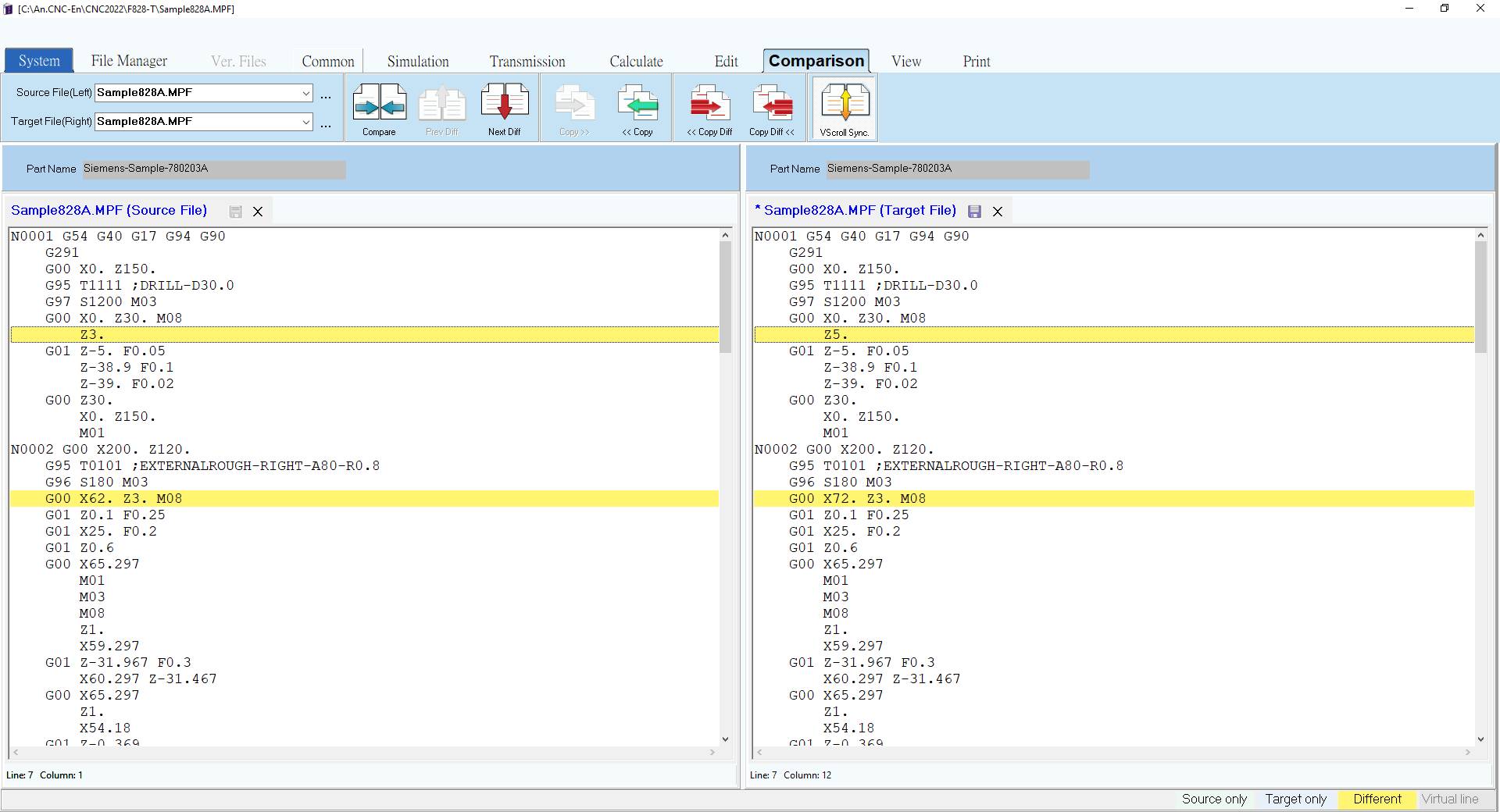

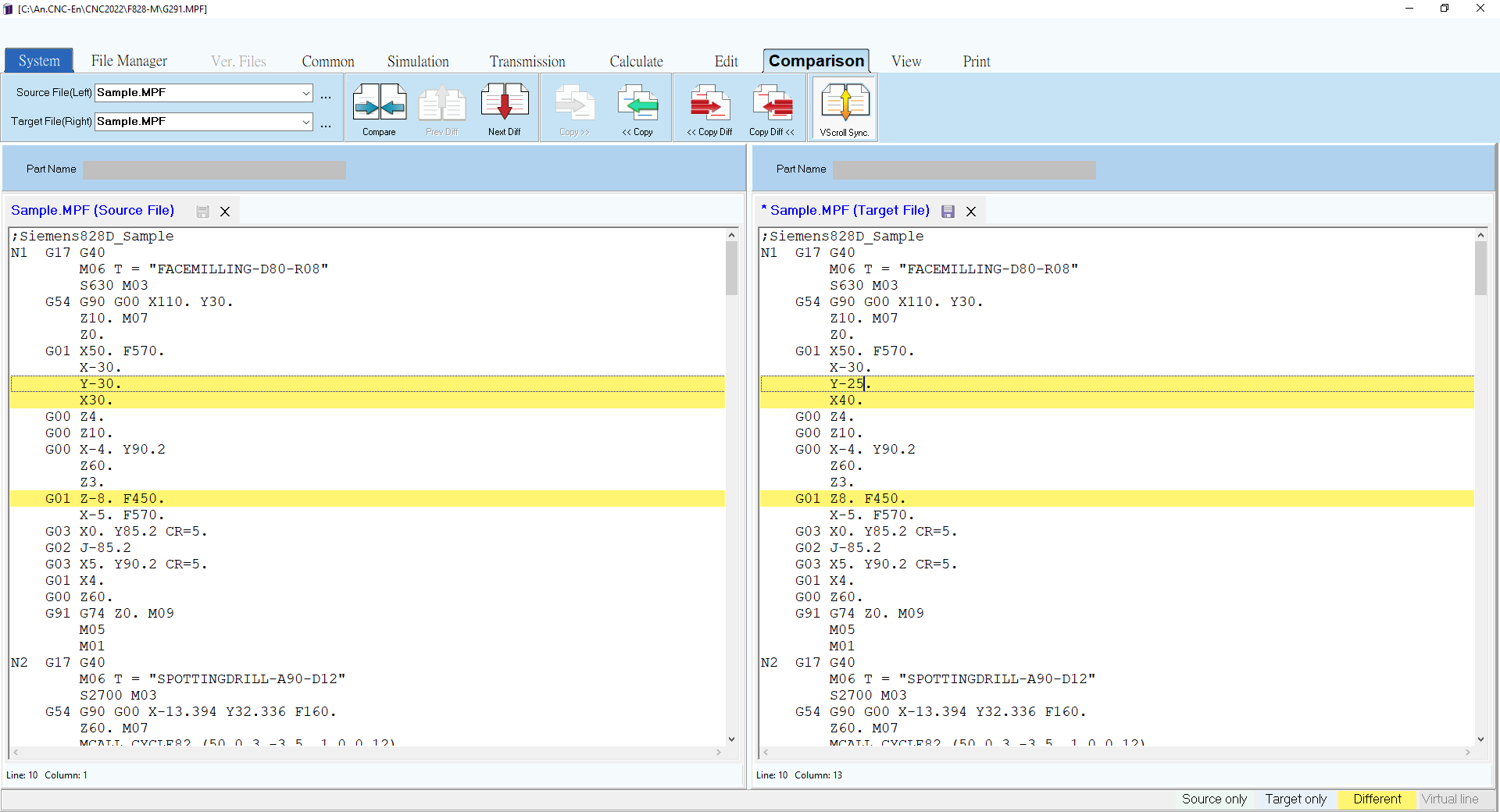

2.5 Comparison:

(1) Comparison between source file and target file

(2) Color displayed for difference inspection: Source only, target only, different

(3) NC code comparison rule: space, empty line, comments in the parenthesis

(4) Content difference synchro: copy line, copy difference, Sync-scrolling inspection

(5) Program comparison setting:

(a) Space & comment: set the comparison of the space, empty line, and comments

(b) Font: Font, font color, and background color setting for identical, different, source only, target only, virtual line

3 Program Simulation

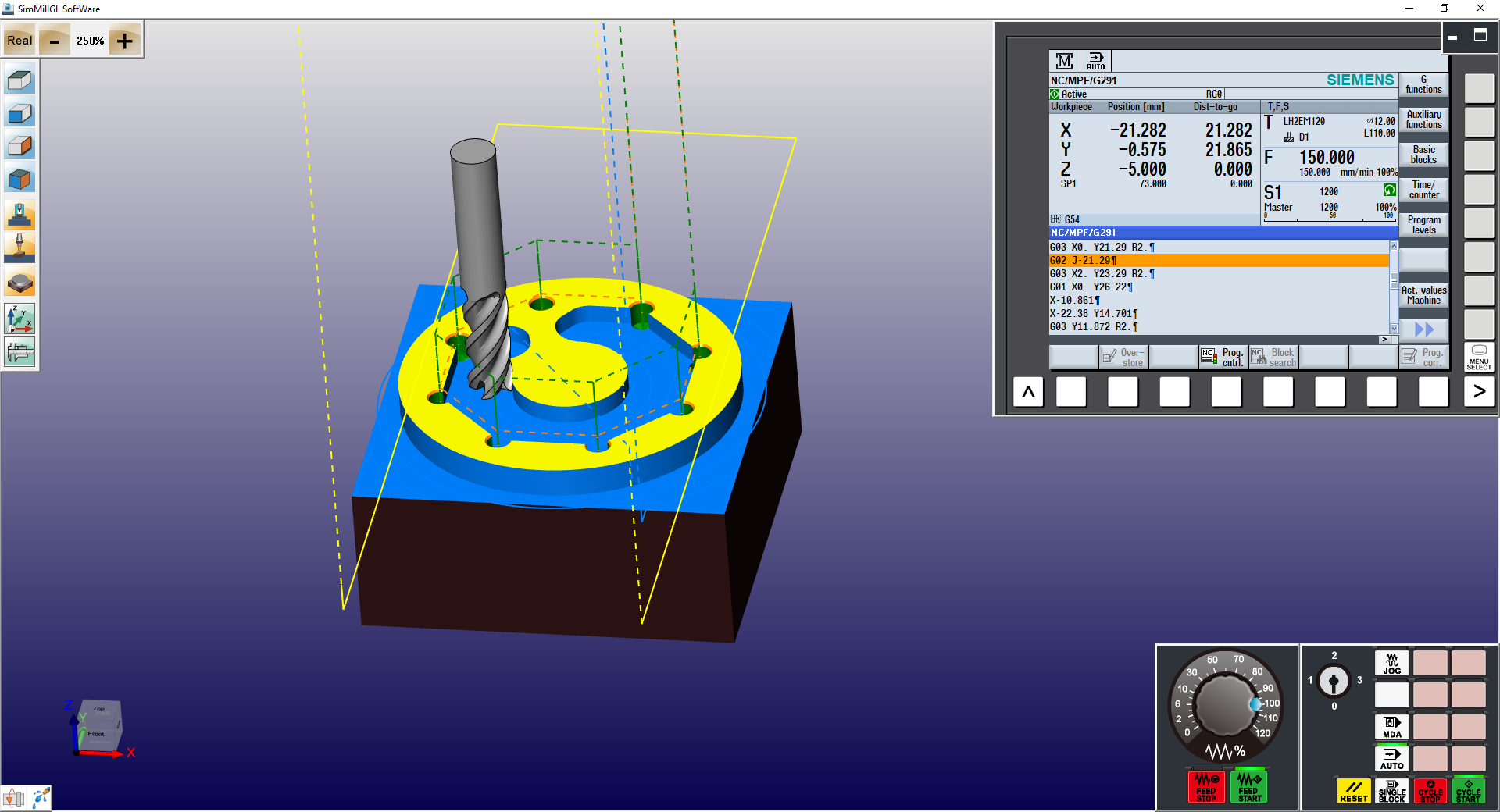

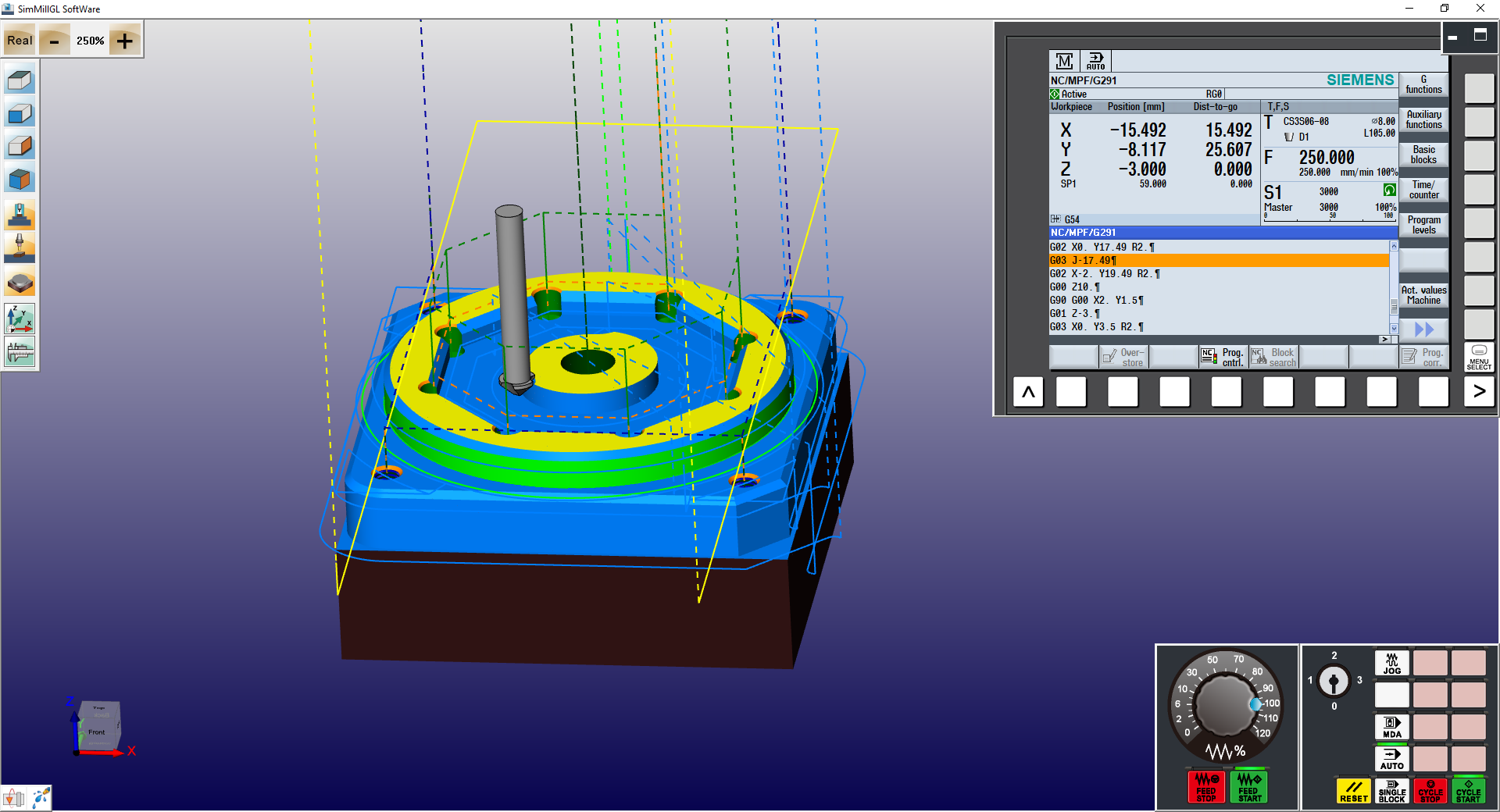

3.1 SIEMENS Simulation: Machine type, turning /milling simulation, machine turret/magazine

(1) Machine type: select the machine type for simulation

(2) Milling simulation: cutting path and solid simulation

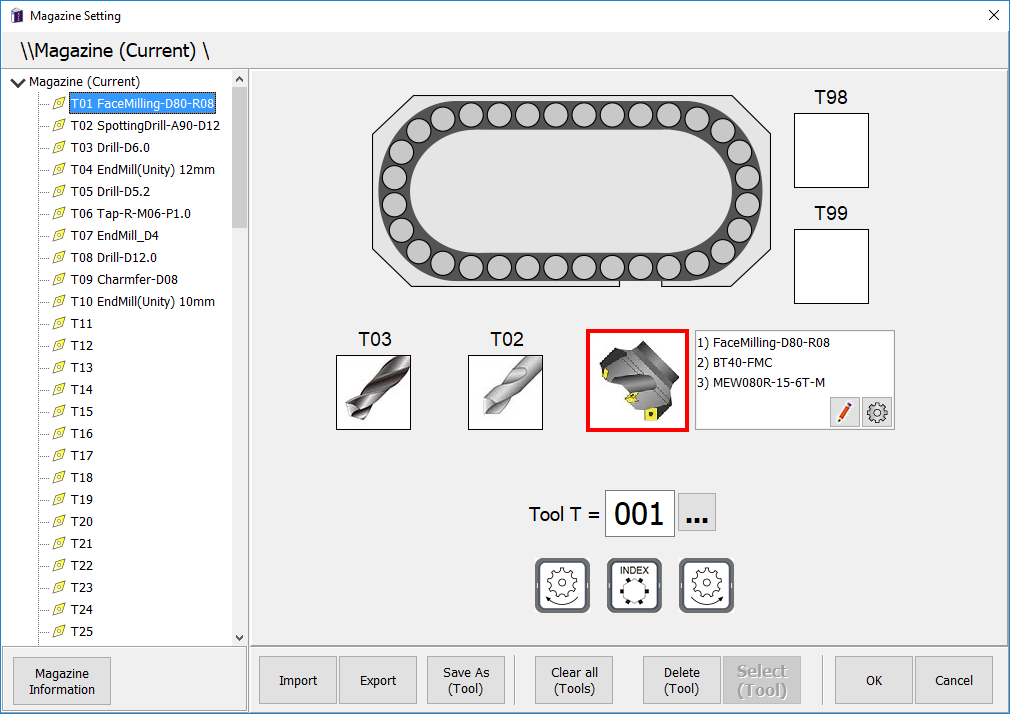

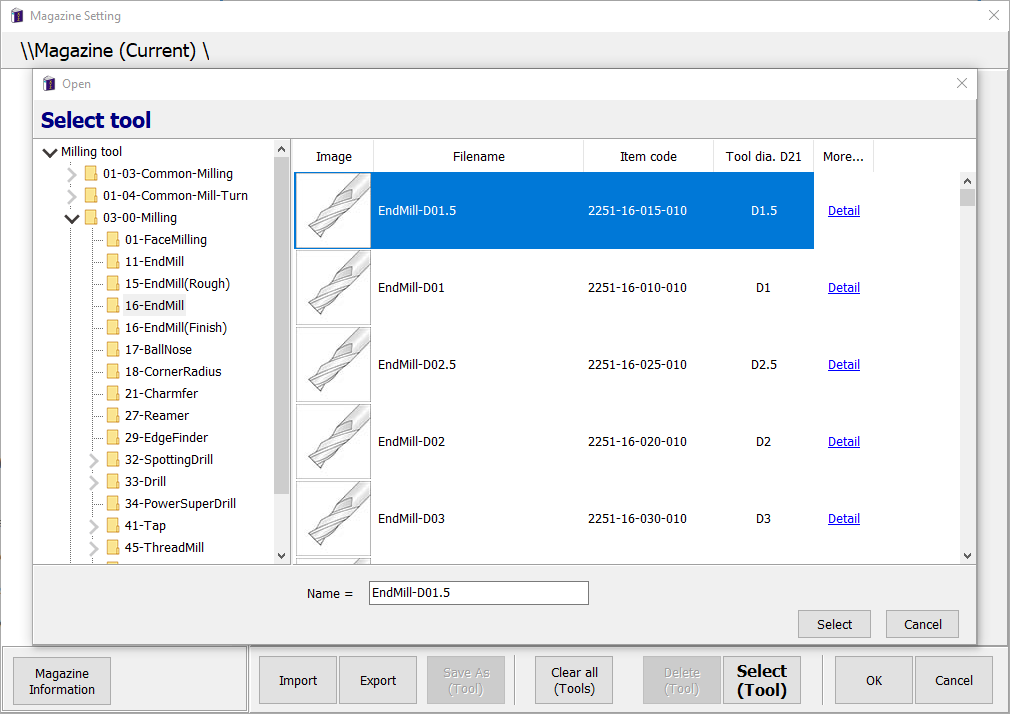

(3) Magazine/Turret: set the applied tool of the CNC program

(a) Magazine (Milling): FaceMill, EndMill, Ball, Corner radius, Chamfer, Edge finder, Spot Drill, Drill, High Speed Drill, Tap, Thread Milling, Rough Boring, Finish Boring

Professional Version Additional Features

3.1 Program simulation:

(1) Turret/Magazine: Set the applied tool of the CNC program

(a) Set tool basics: Add or modify tool data

(b) Common Turret/Magazine: Build and set multiple groups of commonly used turret/magazine

(c) Turret/Magazine import/export: Save and import in Turret/Magazine

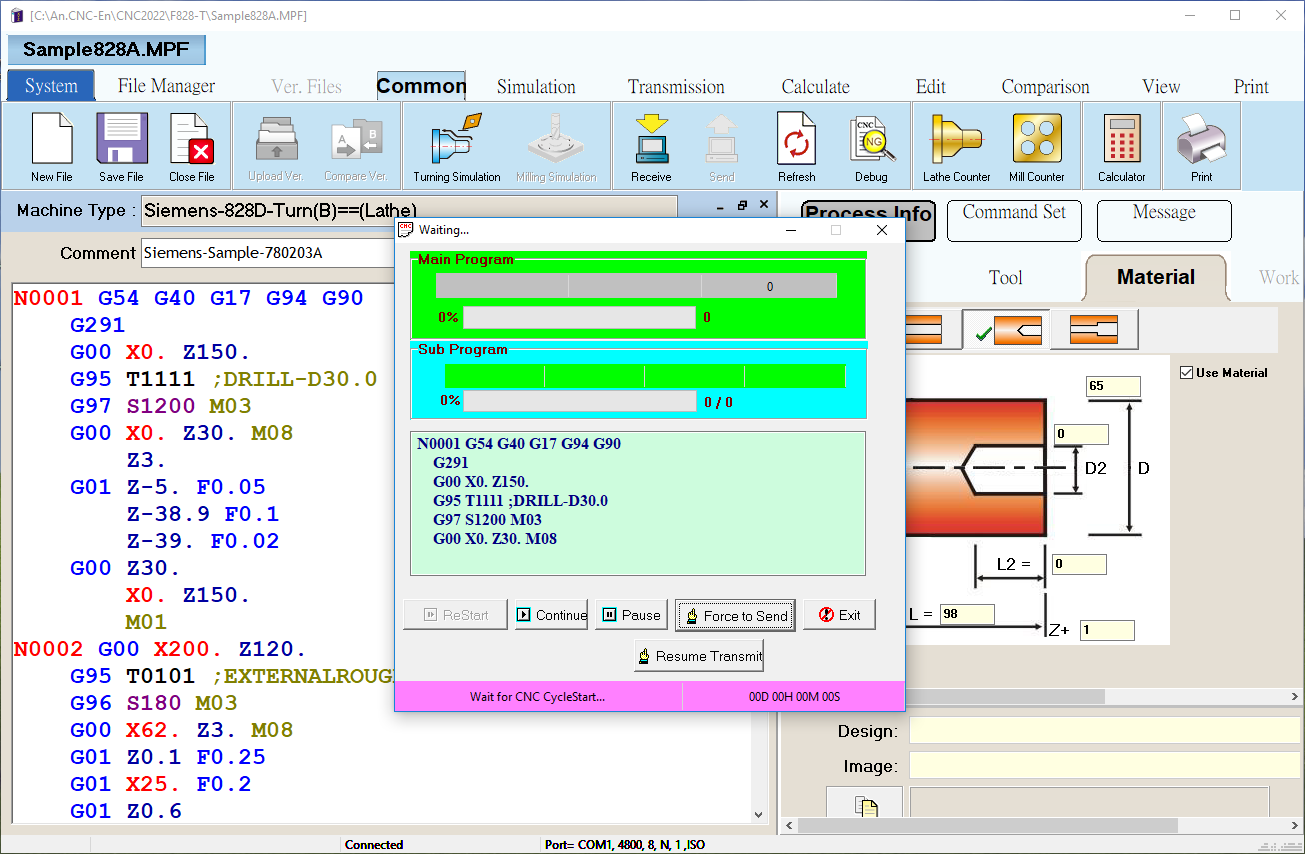

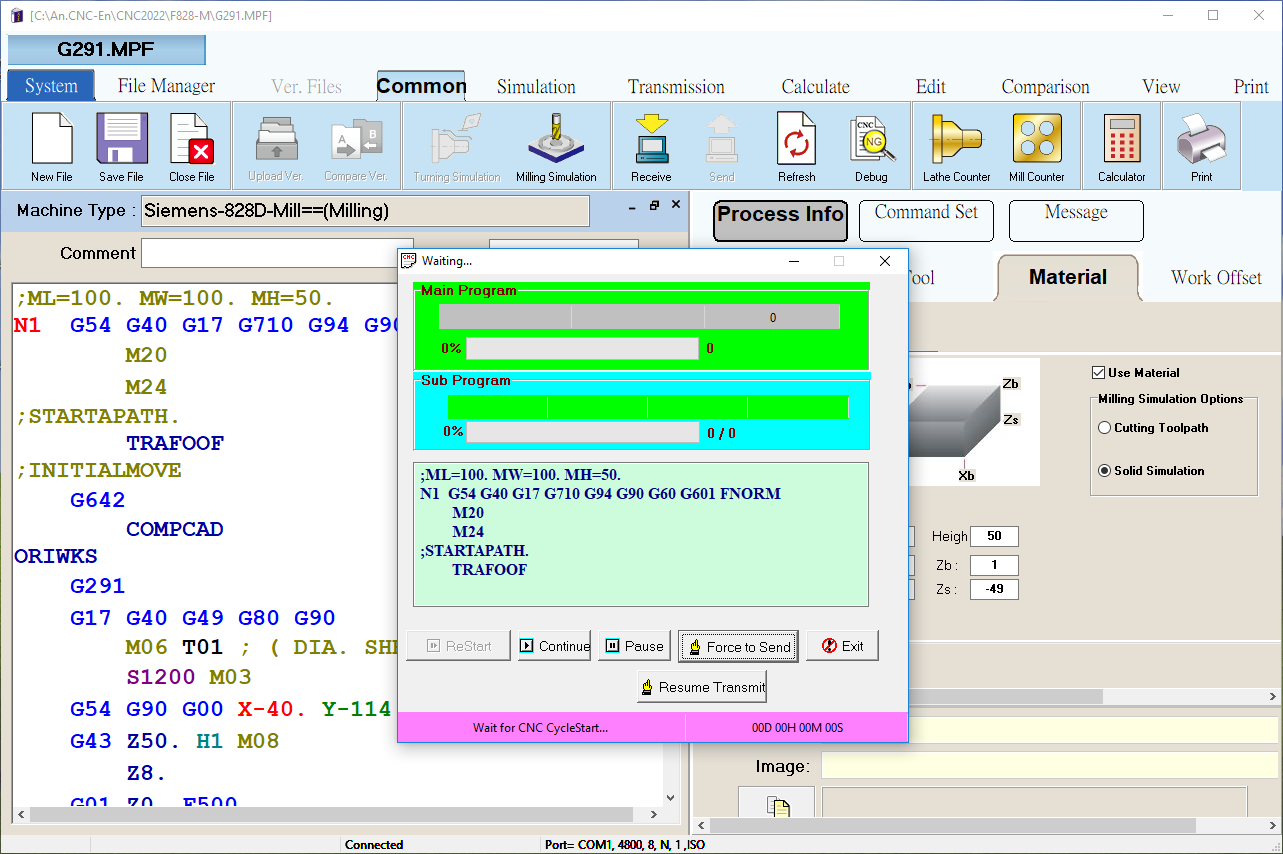

4 Transmission

4.1 Transmission:

(1) Send & Receive: Connect to the machine to transmit CNC files

(2) iNcFile (purchased separately): Open iNcFile to import/export files

Professional Version Additional Features

4.1 Transmission: remote transmission mode

(1) Remote: Enable program transmission through the command on the machine end

(a) Transmission:

Transmit programs from machine to specified folder

(b) Search: Request to send back the file list in the specified folder on the computer end to machine end

(c) Reply: Request to send back the CNC programs specified by the computer end to machine end

(d) Set F code folder:

F code group: Divide the function in groups and distribute to different machine

F code:

Build or modify F code in specified group

Set the path of specified folder with F code

Use F code to specify the folder while remote controlling